WELCOME TO SHANDONG SHANGDA MACHINERY CO., LTD.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-29 Origin: Site

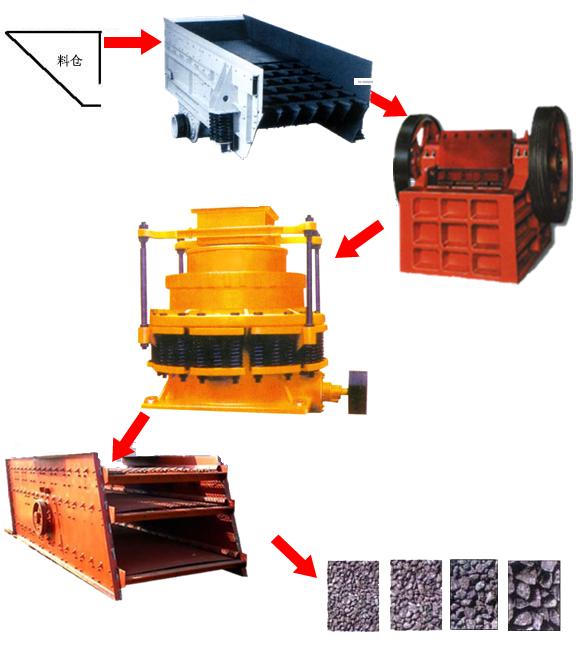

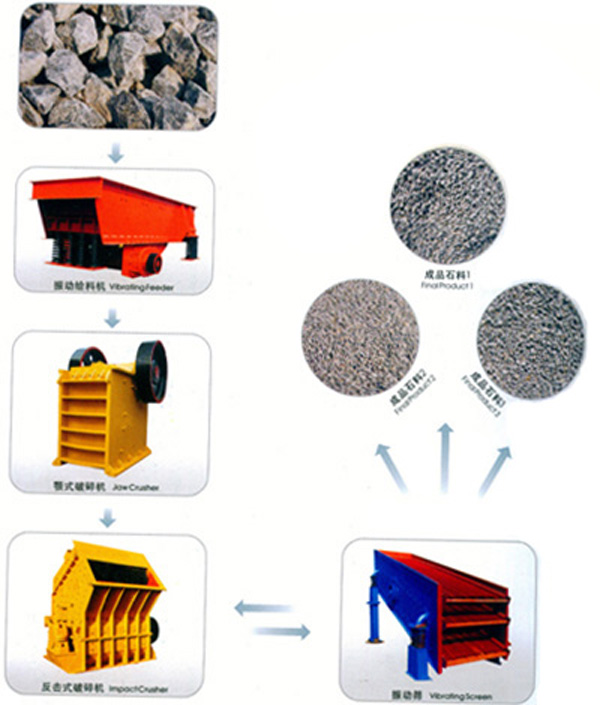

A granite crushing production line is a systematic set of equipment designed to process raw granite into various sizes of construction aggregates, which are widely used in infrastructure projects like highways, bridges, and building construction.

Vibrating Feeder: Uniformly feeds large raw granite blocks into the primary crusher, preventing equipment overload.

Primary Crusher: Usually a jaw crusher, which breaks large granite blocks (up to 1.5 meters) into smaller chunks (around 300-500mm) for subsequent processing.

Secondary Crusher: Common types include cone crushers or impact crushers, which further reduce the granite chunks to 50-150mm, improving particle shape and uniformity.

Vibrating Screen: Separates crushed granite into different particle sizes. Qualified aggregates are sent to the finished product pile, while unqualified ones are returned to the secondary crusher for reprocessing.

Conveyor Belt: Connects all equipment in the line, enabling continuous and automated material transportation throughout the production process.

High Efficiency: The automated workflow minimizes manual intervention, with a daily processing capacity ranging from 500 to 10,000 tons, adapting to both small and large-scale projects.

Superior Product Quality: Through multi-stage crushing and screening, the final granite aggregates have a regular shape, stable particle size distribution, and high compressive strength, meeting strict construction standards.

Strong Adaptability: The line can be customized according to specific requirements (e.g., different aggregate sizes or output capacities) and is suitable for processing various hard granite types with compressive strength above 150MPa.

Infrastructure Construction: Provides high-quality aggregates for highway subgrades, bridge foundations, and railway ballast.

Building Industry: Supplies materials for concrete mixing, wall masonry, and floor paving.

Landscape Engineering: Processes granite into decorative stones (e.g., paving stones, curb stones) for parks, squares, and residential communities.