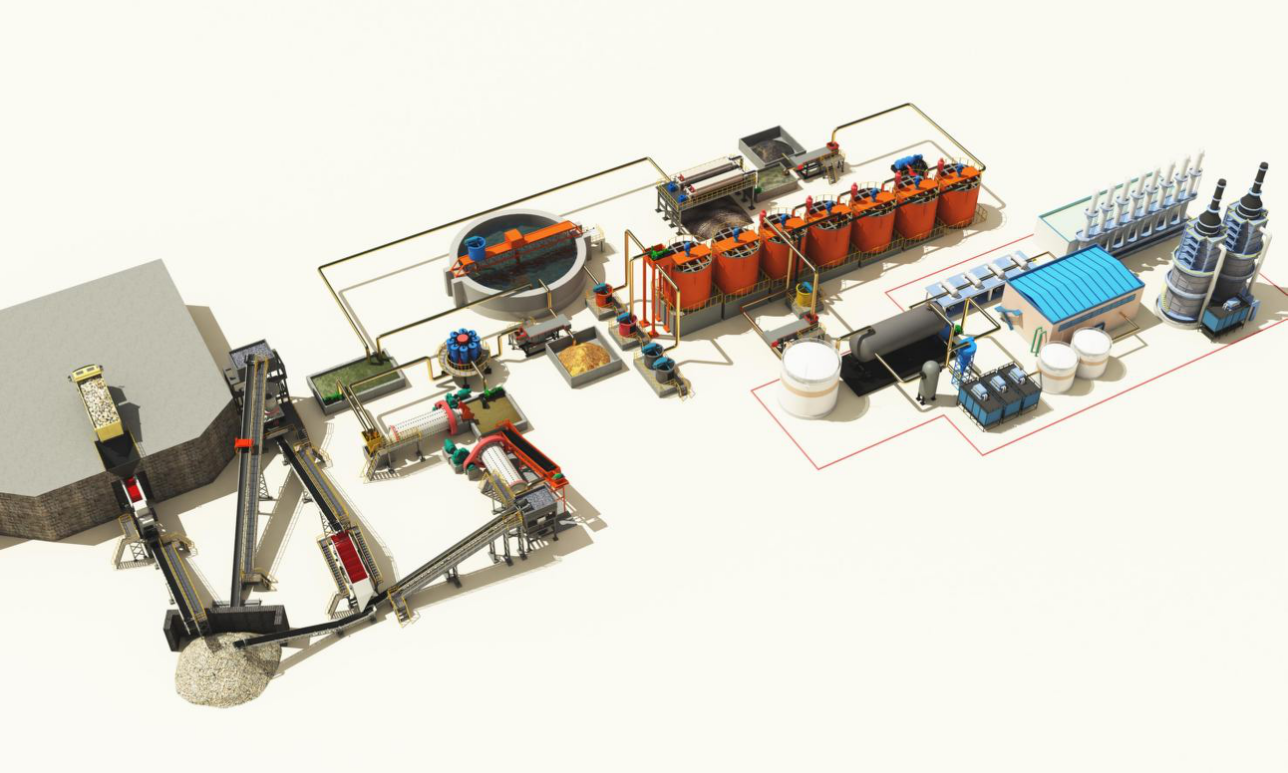

First, raw gold ore is crushed into small particles by jaw crushers and cone crushers, then ground into fine powder via ball mills to liberate gold particles from gangue. Next, beneficiation methods such as flotation, gravity separation, or cyanidation are applied to concentrate gold. Flotation is suitable for sulfide ore, while gravity separation works well for placer gold. Cyanidation, with strict environmental controls, is widely used for high recovery rates.

Finally, the concentrated gold is refined through smelting or chemical processes to produce high-purity gold products (e.g., gold bars). Equipped with advanced automation systems, modern production lines ensure stable operation, reduce energy consumption, and meet international environmental standards. Customizable configurations are available to adapt to different ore types, capacities, and regional requirements, making them ideal for mining projects worldwide.